Annalisa Hultberg, Extension Educator, Food safety

Your hard-working wash and packing line equipment might be seeing a lot of carrots and their soil these days. Hygienic design is the principles of equipment design with cleanability in mind so that the excess soil and filth does not build up on the equipment. All equipment that you use during postharvest activities on the farm such as conveyors, barrel washers, brush washers, dunk tanks and spray tables can be assessed with hygienic design in mind.

Bacteria are very, very tiny. They can survive in small bumps, cracks and welds in equipment and tools. If given the right conditions (water, warmth, humidity, oxygen), bacteria can grow exponentially and form a "biofilm", which is a layer of slime. Picture the slime that builds up on a fishbowl or your dog's water bowl; that is from secretions from microorganisms. The goal is to design and purchase your equipment with easy cleaning in mind to avoid the accumulation of this biofilm, which can trap pathogens and cause cross contamination of your fresh produce.

Washing the inside of a brush washer before use

Photo: Anne Sawyer

Some farms build their own equipment or repurpose it from other old materials, which might make the equipment difficult to clean and sanitize, with hidden nooks and crannies where material can build up. But even new equipment can be challenging - sometimes equipment is not designed to be cleaned or easily accessed, unfortunately. Brush washers have sponge rollers that can be difficult to replace, and that stay damp. Sometimes equipment does not fully open so you can't access it to clean it.

These brush roller sponges have gotten old, crumbly

and are a potential source of contamination.

Photo: Michele Schermann

See this excellent factsheet on Hygienic Design for Produce Farms from the University of Vermont by Chris Callahan with more detailed information on these concepts. The following information was drawn from this material and is a shortened overview.

The five key principles of hygienic design for equipment on produce farms are as follows:

- Visible and Reachable Surfaces

If you can’t see it and can’t reach it... you can’t clean or sanitize it. The idea with this principle is that you should be able to reach all parts of the equipment to clean it. This does not mean that you must be able to reach all surfaces of the machine at all times; you might need to disassemble it to clean it. You might need a flashlight or small mirror to see all parts of the equipment inside and on the underside.

This barrel washer is an important piece of equipment on the farm for

washing many types of produce. The inside of the barrel can be difficult to reach to clean.

The farm must develop protocols to partially dissemble or come up

with other ways to reach all parts to ensure it is cleaned between uses.

Photo: Anne Sawyer, UMN Extension

2. Smooth and Cleanable Surfaces

Surfaces should be as smooth, cleanable and non porous as possible. This can mean hard plastic, stainless steel or other metals. It generally does not mean wood, which is hard to clean and sanitize. Avoid pitted or bumpy surfaces for food contact surfaces, where bacteria can lodge and grow.

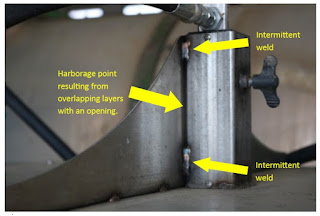

This photo shows a joint with intermittent welds on a piece of equipment

that can cause a gap which can serve as a place where bacteria can accumulate.

It would be better to have a continuous weld that is then ground smooth.

Photo: University of Vermont

3. No Collection Points

Avoid spaces in your equipment where water, food, and other material can collect, called "harborage points.". This might be where water, condensation and produce bits might collect, but not easily seen. The solids can then accumulate in these niches, where they are protected from cleaning, sanitizing and drying properly. It can also cause corrosion and rot in the equipment materials.

This photo shows a collection pan. A collection pan is an intentional collection point that should allow for collected water to easily drain. The rust spots are evidence that it doesn’t drain completely and therefore doesn’t dry easily. An increased pitch in the pan or a “break” in the sheet could create more aggressive draining and better cleaning, sanitizing and drying as a result. The rust also suggests the material isn’t compatible with the use.

Photo and caption: University of Vermont

4. Compatible Material

Consider the materials that your equipment is made from and the chemicals you use to clean and sanitize it. Incompatible materials can cause paint to flake and rust prematurely, which can cause damage and potentially contaminate your produce. Generally chemicals are intended and safe for stainless steel and plastic, but think about other parts of your equipment like rubber gaskets, bearings and other parts that might be exposed to cleaning agents.

5. Preventing Contamination

Try to prevent contamination of the equipment to reduce the likelihood that it might then contaminate your fresh produce. This might mean excluding animals from the packshed through doors or curtains that keep out wild and domesticated animals. You can use non-baited rodent traps along the inside walls of the packingshed. Rafter netting can reduce bird roosting in the rafters. Keep the area around the packshed mowed and free of piles of debris like lumber or equipment, as these provide rodents or other wildlife a place to hide.

This weighted netting keeps animals out of the packshed, but allows for air circulation

Photo: Michele Schermann

Remove culls at the end of the day, sweep and mop the floor, and clean the drain regularly to reduce any attractants for rodents.

For more information

See this blog post on Hygienic Design for Produce Farms from UVM with more information on these concepts. The post also has a link to an Excel doc checklist.

UVM Extension and MSU Extension has also created a very interesting interactive video on hygienic design principles. This video allows you to virtually walk around a piece of equipment to give you an in-depth look at these principles.

Explore this video here: http://go.uvm.edu/hygienicdesign

Comments

Post a Comment