Annalisa Hultberg, Extension Educator, food safety

The flow and design of a packshed is a critical but often overlooked aspect of fruit and vegetable operations. Packsheds do not need to be expensive or constructed with all stainless steel equipment to be safe, efficient and comfortable places to wash and pack produce. Here are some tips for designing and maintaining a packing area this coming season.

Understand and follow principles of hygienic design for your packing area

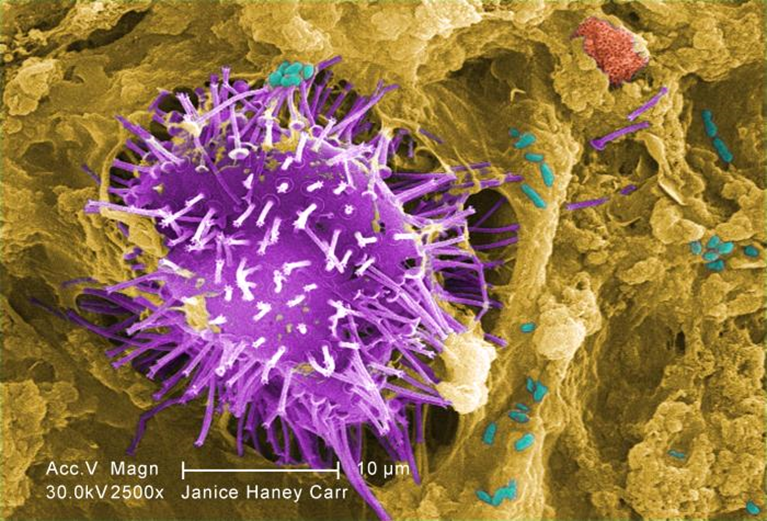

Hygienic design is a set of principles that apply to processing, packing and washing areas to ensure that they are cleanable, washable and sanitizable. Some very helpful new resources from the University of Vermont Extension Ag Engineering program include packshed designs and information to help you guide your packing area set up. For example, your equipment should be easily accessed for cleaning, with smooth and cleanable surfaces. You can learn more about ideal finishes for food contact surfaces here. Wood, pitted or bumpy surfaces are not easily cleaned, and can harbor microscopic bacteria, so should be avoided in the packing area when possible.

The key elements of hygienic design include:

- Visible and Reachable Surfaces

- Smooth and Cleanable Surfaces

- No Collection Points

- Compatible Materials

- Preventing Contamination

This short case study of Small Axe Farm in Vermont provides packing area guidelines and best practices, including many photos and a schematic for sample packshed flow and design. A video case study of the farm is available here.

Use spray tables and equipment on wheels

There are many spray tables design and options that are available to help guide your decisions as you consider installing a spray table. Spray tables are an excellent way to spray down roots and other study vegetables this summer, and can improve food safety as the water is single pass over the produce, as opposed to a dump tank where water recirculates and contaminants can spread via the water more easily. For more information on washing and packing vegetables for postharvest quality, see this page from UMN Extension.

Avoid standing water

Standing water on the floor is a breeding ground for Listeria monocytogenes, a pathogenic bacteria that can multiply in packing areas, grows well in cold conditions and contaminate fresh produce. Many recent outbreaks have been traced back to Listeria, so it is important to do everything you can to minimize the risk of this bacteria spreading and taking hold in your packing area.

Floor drains, grading of floors for drainability, and squeeging floors nightly are ways to reduce standing water and therefore the spread of Listeria.

Comments

Post a Comment